ProSlab™ Cold + Freezer

About

ProSlab is an engineered approach to the construction of concrete floors and allows for up to an 80% reduction in joints. The ProSlab steel fiber reinforced floor slab design offers a flat, smooth, and virtually curl-free floor with fewer joints. Using steel fibers, a time-tested technology, ProSlab is superior to commonly designed slabs.

Better Floor Slabs

To improve the quality of concrete floors, you must address their weakest point: the joints. The easiest way to control this issue is to decrease the number of joints without increasing the number of random cracks. Contrary to general opinion, it is possible to control cracking in concrete floors. Success depends on an understanding of the causes of cracking and a readiness to do what is necessary to prevent these causes and control the location of joints. This is one of the benefits of using a proactive reinforcement like CFS Steel Fibers. Often only a little extra planning and effort are required. Let CFS’s experienced team assist you obtain superior results on your next project.

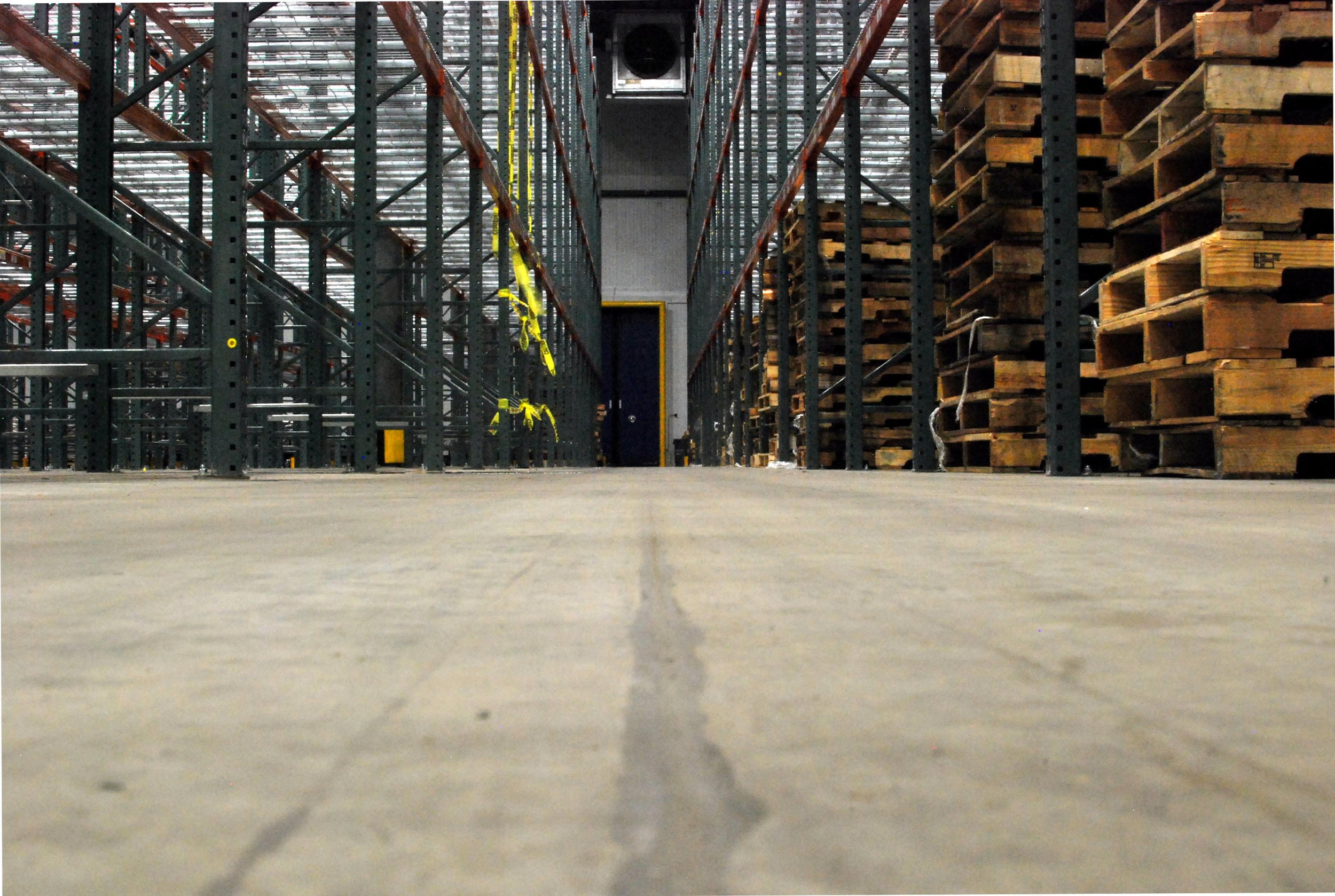

The ProSlab floor system–with up to 80% fewer joints than a conventional warehouse floor–is constructed to maximize material handling speed, reduce equipment maintenance costs, and minimize lift truck operator fatigue. The ProSlab floor system uses steel fibers as proactive reinforcement to control cracking and curling and extend joints out to 150’. These durable floors are designed to stand up to the constant pounding of forklift and pallet jack wheels, which are joint destroyers.

Although ProSlab eliminates up to 80% of joints, attention must be paid to the remaining joints. All joints in ProSlab floors have positive load transfer devices installed and do not rely on aggregate interlock. The shrinkage caused by lower temperatures causes the joints to open wider and make aggregate interlock ineffective.

Armored joints should be used in some areas. The width of the joints and the size of the wheels on the material handling equipment will determine where and when they should be used. During the design process, CFS engineers will work with you to determine joint placement.

Case Studies

WhiteWave Foods

Harrisonburg, VA

McCook Cold Storage

McCook, IL

Literature

ProSlab Cold + Freezer Benefits

Reduced Number of Joints

Of specific importance in this environment is the spacing of control joints for two reasons: First, pathogens grow in these joints; significantly reducing the number of joints results in drastically reducing pathogen accumulation as well as markedly simplifying floor maintenance. Second, the wear and tear on equipment is radically reduced. In a building with conventional joint spacing, a forklift or pallet jack crosses more than TWENTY joints over 350’; in the same building with a ProSlab floor (see diagram from the freezer of Cheryl’s Cookies below), the equipment encounters just TWO joints.

Reduced Curling

Extended joint spacing and steel fibers prohibit a floor from curling at the joints, which is especially important in cold storage/freezer floors. Due to the design of insulation and vapor barriers, excess water in the slab must exit through the top of the slab. Steel fibers allow for the development of micro-cracks, which are not visible and form critical hinges. The weight of the slab and gravity take over to eliminate the vast amount of curling.

Cheryl’s Cookies (owned by 1-800 Flowers): “At the sawn joints, I see no evidence at all for curling.”

–George Garber, concrete flooring consultant

Flat Floors

An integral part of a freezer or cold storage construction project is a flat, level, and durable floor slab. Automated storage and retrieval equipment is becoming more common, and these automated systems require specially-designed floors. Building heights are increasing (it’s less expensive to build a cold storage facility up than out), and so are owners’ expectations of performance (it’s imperative to keep the expensive equipment running at full capacity), which contributes to the demand for better floor slabs in these facilities.

Increased Flexural Fatigue Resistance

The flexural fatigue resistance at two million cycles for plain concrete is approximately 50% of the modulus of rupture. This the basis for the well-known safety factor of 2 used in design guides. Steel fiber mixes have shown fatigue strengths of 65% – 90% of the modulus of rupture. This means longer lasting floors for you.

Impact Resistance

The impact resistance of a ProSlab floor is 3 to 10 times greater than a plain concrete slab. Concrete is inherently brittle, and the typical concrete floor section is in tension and under flexural stress. By adding CFS steel fiber–three-dimensional reinforcement throughout the concrete section–a composite material of steel and concrete is created. The distribution of the steel fiber imparts ductility to the concrete, therefore increasing the impact resistance of the section.

Cost Effective

There are other methods for extending joints, such as shrinkage compensating additives and post-tension. Compare the cost of ProSlab™ by CFS due to its ease of installation, no checkerboard pours, and lower material cost. Find out why ProSlab is your best choice.

CFS Engineering Support

Concrete Fiber Solutions engineers partner with you from project specification to completion. Every detail is carefully considered. In a refrigerated room, graduated temperature reduction controls cracking caused by differential thermal contraction and allows drying to remove excess moisture from the slab. We will include a temperature draw down schedule for each project.