ProSlab™ Extended Joint

About

ProSlab™ by CFS is a concrete floor slab design that offers flat, smooth, and virtually curl-free floors with fewer joints by using a time-tested technology that has proven to be superior to the commonly used slab designs. This technology, also referred to as wideslab construction, is a method of designing and constructing a slab-on-ground in which individual slab panels extend a minimum of 50’ in at least one dimension. Wideslab construction relies on methods other than joints to control cracks and curling. ProSlab uses single course installation giving the slab continuity from “top to bottom.” Our floors provide a beautiful, durable finish that meets or exceeds design requirements and owners’ expectations.

While many owners, developers, and engineers consider wideslab construction a new process, Mike McPhee (a voting member of ACI 302 and ACI 360) has been an innovator in wideslab design, using steel fiber technology, for decades. It wasn’t until 2015, two years after starting Concrete Fiber Solutions (in partnership with Global Material Technologies), that the term “wideslab” was truly recognized within construction nomenclature. And shortly thereafter, CFS branded Mike’s design concept with the ProSlab™ name.

The tremendous benefits wideslab floors offer are the solutions that manufacturers with diverse product lines and production needs have been seeking for years. Large food companies such as Whitewave Foods have installed ProSlab floors because they have significantly less maintenance issues with fewer joints and cracks. Precision manufacturing companies such as Woodward find the elimination of cracks and curling in their ProSlab floors to be an integral element needed to achieve the highly calibrated products they produce. Additionally, leaders in the logistics real estate market such as Prologis have embraced the ProSlab™ by CFS design. In addition to the other benefits, the flat, minimally-jointed floors are ideal for warehouse automation.

The CFS team has over 20 years’ experience designing steel-fiber-reinforced, extended-joint floors, providing superior engineering, expert installation, and precision manufacturing. Consisting of steel fibers manufactured by Concrete Fiber Solutions, there is no better flooring system available today. These original steel-fiber-reinforced floors are still in use, providing the owners with the floor and performance they expected. The CFS team provides expertise in every step of the process and will bring new ideas to fiber design, mix design, and construction practices to meet the challenges of the next 20 years.

Success is in the details.

Case Studies

Prologis

Juarez, Mexico

WhiteWave Foods

Harrisonburg, VA

Woodward, Inc.

Rockford, IL

ProSlab Extended Joint Benefits

Reduced Number of Joints

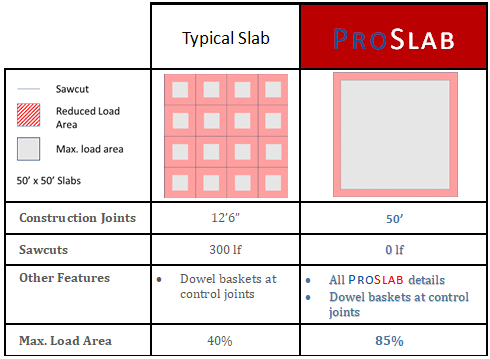

Joints are reduced by as much as 80%. In a building with conventional joint spacing, a forklift or pallet jack crosses more than FORTY joints over 500’; in the same building with a ProSlab floor, the equipment encounters just FOUR JOINTS.

Reduced Curling

Extended joint spacing and steel fibers prohibit a floor from curling at the joints. Steel fibers allow for the development of micro-cracks, which are not visible and form critical hinges. The weight of the slab and gravity take over to eliminate the vast amount of curling.

Flat Floors

ProSlab extended-joint construction ensures a flat, level, and durable floor slab. Automated storage and retrieval equipment is becoming more common, and these automated systems require specially-designed floors. Forklifts are joint destroyers, so the fewer joints the better!

Increased Flexural Fatigue Resistance

The flexural fatigue resistance at two million cycles for plain concrete is approximately 50% of the modulus of rupture. This the basis for the well-known safety factor of 2 used in design guides. Steel fiber mixes have shown fatigue strengths of 65% – 90% of the modulus of rupture. This means longer lasting floors for you.

Impact Resistance

The impact resistance of a ProSlab floor is 3 to 10 times greater than a plain concrete slab. Concrete is inherently brittle, and the typical concrete floor section is in tension and under flexural stress. By adding CFS steel fiber–three-dimensional reinforcement throughout the concrete section–a composite material of steel and concrete is created. The distribution of the steel fiber imparts ductility to the concrete, therefore increasing the impact resistance of the section.

Cost Effective

There are other methods for extending joints, such as shrinkage compensating additives and post-tension. Compare the cost of ProSlab™ by CFS due to its ease of installation, no checkerboard pours, and lower material cost. Find out why ProSlab is your best choice.

CFS Engineering Support

Concrete Fiber Solutions engineers partner with you from project specification to completion. Consideration for every detail is carefully considered.