The Edge is the Enemy

Some people like to live on the edge. They say the most interesting things happen there, and they are right. But there is a catch: not all those interesting things are good.

When it comes to ground-supported concrete floor slabs, lots of interesting things happen at the edge, and all of them are bad. The edge is where joints spall, where curling shows up, where differential movement occurs, and where structural failure from overloading begins. The edge is where joints need to be filled, and refilled, and refilled again. The edge is where costly load-transfer devices are installed, and where those devices sometimes fail. In contrast, the slab interior, away from the edges, is a peaceable kingdom where few bad things happen.

Photo 1

Poorly made sawn joint in a new concrete floor. This can only occur at a slab edge.

Photo 2

Spalling and faulting at a joint in an old concrete floor. Damage like this can only occur at a slab edge.

Conventional floors have edges all over, so it’s no surprise they have problems galore. The typical industrial floor of today is criss-crossed by joints spaced 12 to 14 feet apart. Every one of those joints creates two slab edges. The result is a collection of tiny slabs in which 67 to 75% of the surface area lies within 3 feet of an edge.

But floors don’t have to be built that way. A CF·Slab wide-slab floor, with steel fibers to control cracks, can be built with joints spaced up to 125 feet apart. While the CF·Slab system doesn’t get rid of every edge (no method can), it eliminates 80 to 90% of them. A CF·Slab floor consists of a few big slabs, with less than 10% of the surface area lying within 3 feet of an edge.

Figure 1

Shows a conventional floor with lots of edges. The floor is 120 ft wide and 240 ft long. Joints are spaced at 12 ft. Shaded areas lie within 3 ft of an edge.

Figure 2

Shows a wide-slab floor with far fewer edges. The overall floor dimensions are the same as in Figure 1, but here joints are spaced at 120 ft. Very little of the floor area lies within 3 ft of an edge. (The 3 ft dimension is arbitrary. If you believe edge effects extend more or less than 3 ft, feel free to redraw these sketches with the dimension of your choice.)

Getting rid of the edges brings many benefits. Some of those benefits are easy to see, while others are less obvious but no less important.

The more obvious benefits tend to be the linear ones — those for which the effects are roughly proportional to the total joint length. Cut the joint length by x%, and certain costs go down by something close to x%. The obvious linear benefits include lower costs for dowel bars, joint sawing, joint filling, joint maintenance, and grinding at curled edges. A less obvious linear benefit is reduced wear and tear on forklifts and other warehouse vehicles.

The less obvious benefits tend to be nonlinear. In these cases deleting joints doesn’t help at all till the reduction reaches a critical level, and then the effect is sudden and large. Nonlinear benefits include the ability to use certain edge details and the option — in some cases — to reduce slab thickness.

Let’s look at the edge details first. There are ways to mitigate edge problems, but they cost money. Even commonly-used details such as dowels and joint filler are sometimes beyond an owner’s budget where joints are closely spaced. If you eliminate enough joints, though, those details become affordable. One highly effective way to reduce wear and tear at slab edges is to armor them with steel bars or steel angles imbedded in the concrete. But armored edges are expensive, and no one has figured out a good way to install them at any joints other than construction joints — so they are rarely used in floors with closely spaced joints. However, once you stretch the joint spacing out to 100 feet or more, armoring the edges becomes practical and is often a good choice.

Another nonlinear benefit is the option to reduce slab thickness. This takes some explaining.

The structural design of a ground-supported floor consists mainly of making the concrete slabs thick enough to support the intended loads without breaking. Structural engineers use many different methods, but most come down to this: the flexural stress within the concrete must not exceed the concrete’s flexural strength, with a safety factor. Higher stress means thicker slabs.

Flexural stress depends on many factors, but a big one is the position of the load relative to the slab edge. Loads in the slab interior — called the internal position — create the least stress. Loads at a slab edge or a slab corner create more stress.

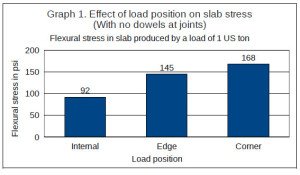

Graph 1

Effect of load on slab – With no dowels

Graph 1 shows the flexural stress created by a load of 1 US ton, at the three possible load positions. The numbers come from Table 3 in Chandler’s Design of Floors on Ground, and are based on these assumptions:

6-inch slab thickness;

200-pci subgrade modulus;

loaded area of 12 square inches;

no dowels at joints.

With the assumptions behind Graph 1, edge stress is 58% higher than internal stress. Corner stress is even worse — 83% higher than internal stress.

Changing the assumptions will change the height of the columns in the graph. But no matter what changes, you can count on this: The stress from edge or corner loading will always be greater than the stress from internal loading.

Don’t load-transfer devices, such as dowels, reduce stress at edges and corners? Sure they do, but no device transfers all the load. See Graph 2. With effective dowels at the joints, the critical load now moves to the edge position, where the stress is 34% higher than the stress from internal loading. The situation has improved, but edge stress is still much higher than internal stress.

Graph 2

Effect of load on slab with dowels

How does eliminating edges affect all this? When a floor has lots of joints, you can hardly eliminate loading at slab edges and corners. Edge and corner loads control the design, and the floor ends up overdesigned for the internal load position.

A CF·Slab wide-slab floor, in contrast, has few joints, so they are easier to miss. In many cases, a little care in locating those few joints can eliminate critical loads at the edge and corner position. The floor can then be designed for the much milder internal load position, allowing a thinner slab. This process works best where the critical design loads come from fixed equipment such as warehouse racks, machine tools, or mezzanine posts.

The thing to remember about the nonlinear benefits is that you don’t get them unless you greatly reduce the number of edges. Minor improvements, such as extending the joint spacing from 12 feet to 20 feet, won’t help. But going to 100 feet or more, as the CF·Slab system makes possible, can pay big dividends.

If you enjoy rock climbing or bungee jumping, step up to the edge and have your fun. But when building concrete floors, it’s time to stop living on the edge.